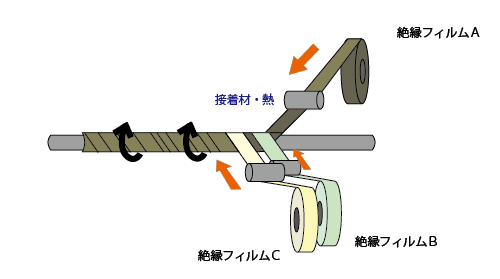

Method

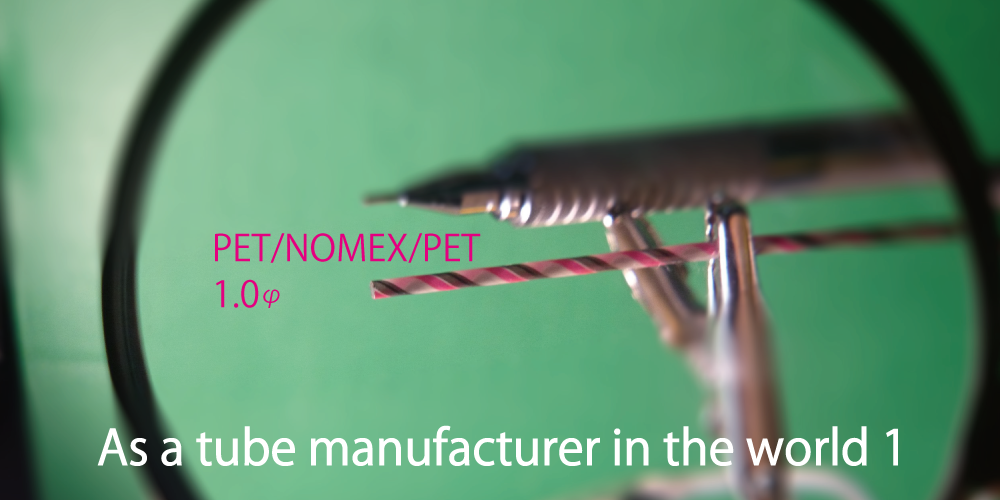

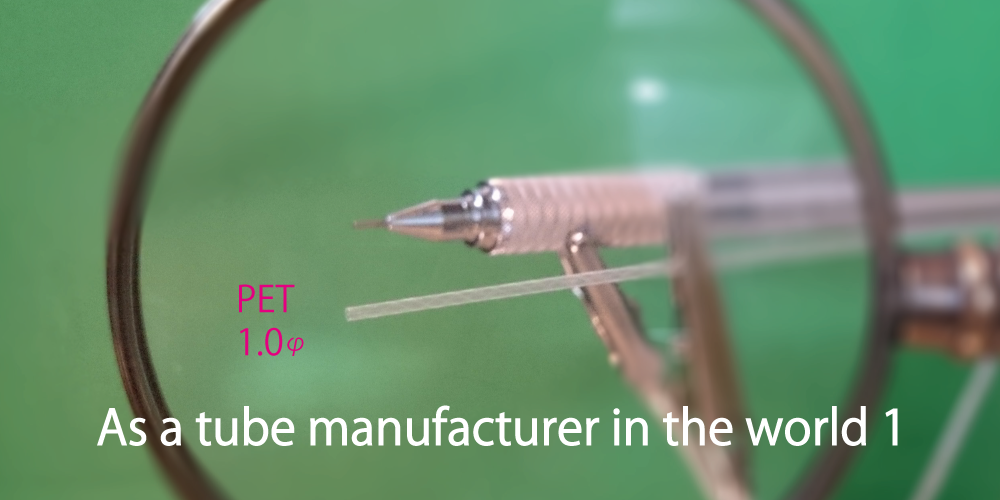

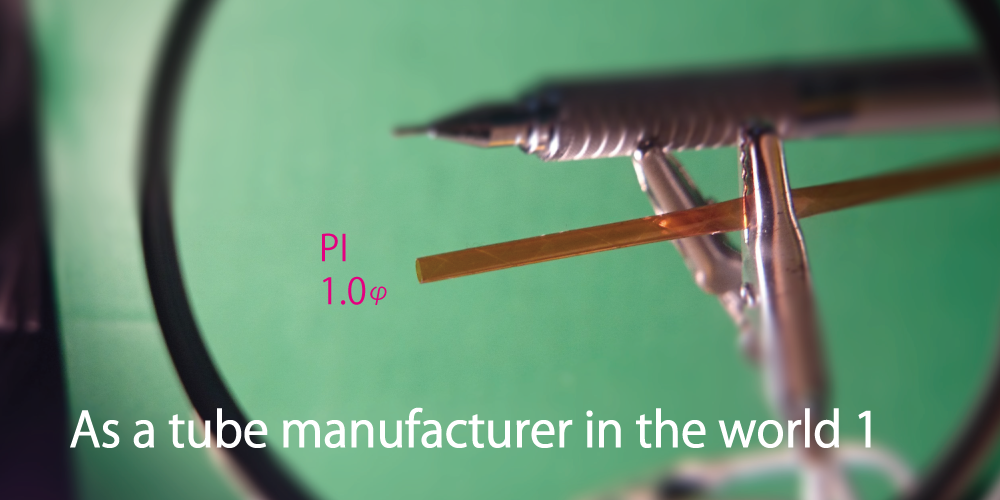

Spiral tube for electric insulation is manufactured by slitting insulation films to make it into 2 to 3 types of tape. After that, as the design on the left shows, it is adhered and solidified it into a spiral shape using appropriate heat and glue.

Inner Diameter

Minimum 1mm φ Maximum 500 φ

Material

PET: Heat Resistance - 150℃

PI: Heat Resistance - 350℃

NOMEX: Heat Resistance - 220℃

PEN: Heat Resistance - 180℃

Nitto’s Insulation Tube

Manufacturing Since 1985

We, Nitto Industrial Corporation, are the pioneers of spiral insulation tube.

From making a general insulator, to processing of battery elements and power-saving products, we work for a wide range of electronic and electrical industry to support the lives of the people.

Nitto Insulator Tube/ Spiral Tube

The name “insulation tube” came from the straw-looking shape of the insulator piece that was made to insulate the connector of the electrical connection, and by making the insulation tube into a spiral shape, it is available in fast delivery and in small sets.

Advantages of the Spiral Shape

By making the insulation tube into a spiral shape, we made it unnecessary for going through the process of molding it into a cast.

We now are accepting orders starting from one unit, which we make as soon as the orders are made. Additionally, our products are available in different and wide range of materials to answer to all the needs of our customers.

From our developed skills, we are able to create in different sizes, materials, and for different needs.

We believe our creation of products that take advantages of the features that films has are infinite.

Solar panel lead tab wiring

Solar panel material